Recreation of the Steinegger & Eshenbaugh Dragster

by John Evans

In 2011 Dean’s Garage published an article featuring the ’60s Phoenix, Arizona based race car—the Steinegger & Eshenbaugh dragster. Dean’s Garage (Gary) had a minor part in the recreation of the retro front-engined rail, the creation of the body wrap depicting photos and articles of the car from the day. John Evans became inspired by the car, and scratch built a scale model. This is his delightful account of building the model.

Inspiration

I stumbled across a picture of the car by chance while researching the ‘net’ for another project (the Allard dragster), and was instantly hooked. I don’t know what it was about this car but I knew that I had to model it. I had in my stash a cast resin kit of a Chrysler Hemi complete with blower which I had bought cheaply several years ago, this would be ideal for the project, so the Allard moved back one place in the priorities and the descision was made.

The inspiration for John Evans’ model. Read the original post about the Steinegger & Eshenbaugh Dragster and its full-size recreation on Dean’s Garage.

The Hemi kit was pulled out from the back of beyond and the parts emptied onto the workbench. It didn’t need a close inspection to reveal that these parts were going to need a lot of work if they were to produce an acceptable model, so I started a closer examination which uncovered some major faults, not the least of which was the angle of the vee, which was about 10 degrees out making it impossible to get both the height and width right. This was very definitely not ideal so the parts were dumped into a temporary spares box and a lengthy cogitation session started.

Now, over the years I’ve had many hairbrained schemes over what I would do when I retired, one of which was to have a go at vac-forming. I had long enjoyed building vac-form kits but, of course, always believed I could produce better ones for myself (my nature, I’m afraid) and to that end I had gathered quite a lot of information including several books, and had even restored an old engine driven vacuum pump (I used to restore stationary engines ‘til arthritis prevented me hauling heavy stuff around), but technology had overtaken me and resin casting had relegated the vac-form to history. So my thoughts turned to resin—surely I could do better than this Hemi kit (there I go again!) The ‘net’ was perused, suppliers were examined, and before long a box full of resin and silicone components landed on my doorstep.

My first efforts were to try to reproduce plastic kit parts from my spares box. Moulds were made, resin was cast, and out came—rubbish. I am a firm believer that the best way to learn was through failure, so it looked as if I was well on my way to becoming a genius! A couple of weeks of perseverance was really all it took to produce some very acceptable castings and the decision was made to scratch build the dragster using all of my own components, a real bonus being that the Allard dragster also used a Chrysler Hemi, albeit a 354 as opposed to a 392. But I am led to believe that externally they are virtually identical I could cast parts for both cars from the same moulds!

My next task was to make my own patterns, or masters.

Masters

I don’t want to come across as any sort of authority on resin casting. Nine months ago I had absolutely no experience of resin or silicone compounds, so it was probably very foolhardy of me to believe that I could achieve any sort of satisfactory result after reading a few articles on the web and watching a couple of You Tubes, but I guess it helps to have a degree of confidence, and it certainly makes you more adventurous. So off I went, carrying with me a huge sackful of beginner’s luck!

At first I thought that I could get away with using old plastic kit parts (suitably modified) from my spares box and set about making my moulds. A couple of days later I was pouring my first serious resin, but although the quality of my castings was acceptable (and improving), nothing looked right. I closely examined the pictures which I had accumulated from the web and realized that the parts were too simplistic and lacking in detail, the only practical solution being to make my own masters from scratch. I could now see that I was becoming very deeply involved with this project so it was at this stage that I made an appeal for any pictures or technical information on the car through the Dean’s Garage website.

At this point Gary became hugely influential on the project by giving me the web address where he had posted all the pictures he had taken. It was hugely influential because many of these depicted the car during its build (or rebuild), enabling me to see the chassis design, detail placements, and mountings (steering box, throttle & clutch pedals, rear axle etc.) and also enabled me to make some reasonably accurate working drawings. Armed with these and many pictures and technical drawings of Hemi blocks, G.M.C. blowers, inlet manifolds, Hilborn injection systems, valve covers, timing covers, axles etc. downloaded from the web I could make my masters.

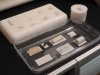

The picture below shows a selection of these masters. Almost anything can be used to make them, the engine block, sump, and inlet manifold are resin with plastic card and rod, the blower, valley cover, and timing chest are plastic card (the blower built up on three internal formers), the valve cover is 1/4” perspex (I’ve placed a raw casting next to it or you can’t see the shape), the rear axle is also 1/4” perspex (turned between centres then filed to finish) with resin & plastic card pinion housing, the injector stack is part of the wife’s hanging basket, and the bug catcher is fashioned from an old toothbrush.

Making a master from resin is a brilliant experience! When I have a casting session I mix the resin and catalyst in a disposable plastic cup,always making more than I need as the last thing you want is not to have enough to fill the mould cavities. This leaves a quantity of resin which will set solid in the cup, and this is later used to make, for instance, the rough master for the engine block. Cut, file, or machine it to the required basic shape, make a silicone mould (inside a piece of plastic water pipe or some such of appropriate size) and cast it in resin. Now the detail work can be done—adding core plugs, stiffening ribs, engine mount lugs, cylinder block offset, and bell housing flanges etc., any way you like to do it, then make another mould. This can be done several times over, as it was to evolve my inlet manifold, and if you find the work was unsatisfactory or you’ve made a mistake, you only have to go back one stage because you’ve got the previous mould to cast it again.

All is Lost

I would very much have liked to illustrate my machine shop set-ups, particularly for the valve cover masters and the front wheel rims (which include the channels for the spokes), but I’m afraid that I had a ‘senior moment’ and deleted the lot from my camera before I had loaded them to my PC! At the same time I lost the early stages of the construction of the engine. I always like to photograph my engineering procedures as my workshop equipment is extremely primitive and therefore my set-ups are often very ‘Heath Robinson’, leading me to forget how on earth I managed to create something. I know that I found a means to hold the 1/4” perspex blocks at the appropriate angles to create those on the top of the valve covers, and the finned area was cut with a 0.02” slitting saw, all on my ancient pre-war mill-drill. The holes had been pre-drilled before slitting so that plastic tube could be pressed in subsequently. The front wheel rims were made entirely on my lathe (an ex-school machine which when rendered obsolete spent several months sitting out in the rain). The rims are each split so six half rims were turned (two for spares/practice) and a small fixture made to hold them in the chuck. There are 36 spokes per wheel so the chuck backplate was removed and a 72 tooth change wheel bolted through from the jaws. The chuck body was then lightly centre punched at 36 positions around the circumference using the change wheel teeth to index. With the chuck and backplate back on the lathe a crude pointer bolted under a bearing oiler enabled the wheel rims to be hand indexed for the 36 spokes. The channels for each spoke could now be impressed into the rim to the correct depth using the handwheel and saddle stop by a specially radiused blade of 0.008” thickness held in the toolpost. Not only did this work beautifully but the blade left a small proud bruise on the inside of the rim for each spoke that nicely represented the nipple seat.

The pictures below show my ancient mill-drill, which is capable of much better work than modern home-workshop machines on account of its immense weight, as long as you’re capable of coping with all the backlash. The other picture is my long suffering and much neglected lathe, showing the 36 centrepots and crude pointer.

Mouldy

A set of photographs from masters to assembled engine. The first shows my favourite method for creating the moulds. The plastic container is the lid from a Ferrero Rocher chocolate box. Each master is superglued to a rectangle of 0.02” plastic card, then glued to the container with P.V.A. glue making sure that there is adequate separation between the components. The container is then filled to the brim with the silicone compound (a quick look on the net will show you how to avoid air bubbles) and left to set. After 24 hours the mould is levered from the chocolate box lid and should result in a set of cavities such as those in the picture. How carefully you lever off the mould is up to you—but if you are ham-fisted you will break the plastic and be forced to buy and eat another box of chocolates before your next session—you have been warned! The P.V.A. glue allows the masters to be lifted off the lid fairly easily and cleaned up ready for next time. The mould for the engine block has been poured into a short section of plastic drain pipe, then pushed out when set.

The second picture shows a set of raw castings straight out of the mould (although as I look at it now I can see that the engine block has been cleaned up ready for use). The blower nose and pulley are not the one used on the model but went through a couple more evolutions to improve its shape and to use a separate pulley. These castings will be rubbed down on wet’n’dry paper using copious quantities of water. When the rectangle (representing the 0.02” card) is very thin move to a fine paper to finish, the rectangle should feather off in one piece just as you’re exactly on size.

The third picture illustrates my favoured method of glueing. Cut a little trench into each of the faces to be joined using a burr, mix up a small quantity of ‘J-B Kwik’ (I like to use wine bottle screw tops for both this and as paint palettes as you just chuck ’em when finished obviating the need to clean, ‘course you have to keep replenishing your supply!) and carefully fill each of these flush with the surface—no more than a MAX 0.005” proud—just enough for the two to amalgamate when pressed together. You have 3–4 minutes to aligne the parts and by 6 minutes it’s permanent, you’ll never get it apart. Brilliant stuff! This method leaves a lovely clean joint line with no messy glue ‘webs’. If you have complicated assemblies—same method—but use J-B Weld, even stronger but takes several hours to set.

The fourth picture is simply all the basic parts of the engine assembled, the fuel pump has been left off owing to its fragility. The blower belt lies in the foreground – made from three folded layers of brandy bottle lead foil and knurled inside with the same devices used to make the moulds for the pulleys—two sizes of Draughman’s compass tops—so the belt fits the knurling on the pulleys. Neat.

It’s All in the Details

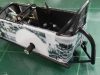

A series of photographs showing the progression of the chassis.

No. 1: The basic frame laid up to align the axle to the crankshaft. The frame is made from aluminium tube – drilled, pinned, then glued.

No. 2: Engine alignment has been determined and front engine mounts are being fabricated and fitted.

No. 3: The Engine can now be dropped into the firewall and front mounts, and the top tubes have been added to the chassis.

No. 4: Now the detail work starts. Front spring seat, front axle radius arm brackets, steering box and shafts, mounts for prop shaft hoop and accelerator pedal, dash panel, push bar, and brackets for safety harness and parachute attachment.

Where there is a Wheel, There’s a Way

The wheels presented me with a huge problem throughout the build. You would think that the narrow spoked wheels at the front would be the biggest problem, but as their difficulty lay only in the method I was confident (there’s that word again) that I would solve it eventually, the rear wheels on the other hand presented me with a different problem ; I just couldn’t get them to look right. It wasn’t the design that frustrated me, it was the finish. I was very happy with the castings I had produced (see pics.) but the wheels on the car were highly polished and reproducing this was tricky. A friend (ex-workmate and fellow modeller) and I had worked for about three years in our spare time trying to produce a paint which would accurately portray the polished metal finish seen on many aircraft. As this would be the Golden Egg for any paint manufacturer we were hugely ambitious, but actually had a considerable degree of success and by using a readily available ‘buffable’ paint and experimenting with different solvents and percentages we achieved the finish seen on the picture of the old Frog Comet (below). This concoction had to be left to cure for at least three weeks after spraying but was ultimately so hard that it could be buffed with abrasive pads ( as indeed the Comet has been) so I was confident that I could achieve the required finish on my wheels. The difficulty lay in the sharp angles and radii which would readily take a good polish but leave the more gentle curves dull, any further polishing would remove the paint from the high spots. I must have made and painted about six sets of wheels before I decided to move on with the rest of the model and hope a solution would present itself.

Fixtures and Fittings

Now that all the various brackets & bits ‘n’ bobs had been added it was time to paint the chassis. I like to ‘scale’ my paints—in fact I would say it was an obsession of mine, so a little matte white was added to the gloss black which just tones down the intensity of the black and takes the edge off the gloss. This turned out to be a far from straightforward job and in fact the whole thing had to be done twice, no one’s fault, it happens sometimes. It’s a fact that I’m still not happy with the finish, but unless you’re aware of the fault you won’t notice it—and I’m not telling!

Next thing was to make the ‘fixtures & fittings’. The exhaust flanges were fabricated from a strip of alloy from the inside of an old micro switch and the pipes are from aluminium tube. Each individual pipe was carefully bent round a very crude jig then subsequently cut to length. The outer ends were bored out using an appropriate size burr, which is amazingly easy because the spherical burr will automatically follow the I.D. of the tube. All these pieces were then coaxed into the correct position using a ‘practice’ engine.

The front axle appears to be offered in two widths, and I am guessing that for the dragster it would be the narrower of the two. I was able to print a large (A4 size) front view of a commercial axle from the web, which I could dimension as my working drawing, then scale down to actual model size and print as a template. One dimension I couldn’t find was the thickness (cross section) and in retrospect I think I have made this too thick, but it was my best guess at the time (old or reproduction American beam axles are as rare as hen’s teeth in the U.K.!). A small piece of 3mm Dural sheet was set up on the mill and the centre section milled to ‘H’ form then drilled and slotted. It was then turned on edge and drilled for the kingpins and radius arm bolts, before the swan necks were hand filed at each end and the centre section similarly filed to size. The whole thing was then put into a toolmaker’s vice with a steel radius template on one side and a hard rubber pad on the other. As the vice was tightened the rubber forced the axle to bend around the template until the correct radius had been achieved. I did photograph these procedures, but as with all the other set-ups they are lost. Oh well, time for a beer!

Brandy and Chocolates

The batwings were simply hand fabricated in three parts from a piece of 1/64” (0.015”) mild steel sheet I had laying around (never throw anything away!) then silver soldered. In the pictures they are shown in their rough state. To complete this assembly the radius arms (hairpins) were made from 0.7mm and 1mm stainless steel wire and again silver soldered, spares were made for all these bits as they are easily damaged or lost (they are in my workshop, anyway). It was obvious that the front suspension was going to be quite a fragile construction so these parts were set aside while work continued on the interior and body panels.

I have no clear pictures of the floor of the cockpit, though it appears to be covered with some sort of carpeting, so I decided to use a little artistic licence and model it as aluminium boiler plate—largely because I had just the material to hand. It comes from the bubble packs holding the pills that my doctor insists I take every day! This material has a diamond pattern embossed into the aluminium foil backing and I could just eke out enough flat area to make the floor in two pieces.

This done I turned my attention to the interior upholstery panels. To make these I needed to simulate quilted leather (or leatherette). The perfect material came to hand in the form of the lead foil capsules on my favourite Brandy bottles, it’s even the right colour—black with a nice sheen! It’s a lovely medium to work with as it doesn’t suffer any of the problems associated with fatigue or work hardening so you can form and re-form as many times as necessary. I have used this many times over the years to simulate drapery such as seat belts or proud hatch covers found on many military vehicles as it will readily accept compound curves. On this model I have already used it for the blower belt and will use it for the safety harness. The quilt effect was created by blunting and burnishing a knife blade then drawing it across the foil over a 1/16” thick card backing. Once the pattern is established the panels are cut and formed to fit the cockpit. By the way, I must emphasize how well Italian ‘Vecchia Romagna’ Brandy and Ferrero Rocher chocolates go together after a day in the workshop!

Reproducing the graphics effectively on the outer body panels required quite a bit of thinking time (I find that soaking in the bath is best for this) but in the end proved quite simple. The templates found on the Deans Garage post for this car were an absolute Godsend. I know that they were changed slightly before final use, but things would have been extremely difficult if not impossible for me without them. The templates were downloaded and resized to fit the model, then composite images made to fit A4 paper, the first had four images each of the left and right panels, and the second had four cowl tops and four back panels. Both these composites were printed as mirror images on clear inkjet decal paper, which was then air-brushed with three thin coats of ‘Johnson’s Klear’ liquid floor polish (known, I believe, as ‘Future’ in the U.S.). This seals the printing so that it’s not affected when soaked in water. When this was thoroughly dried the decal paper was cut into eight rectangles, each containing one print, and the decals were all applied to one side of a sheet of 0.006” clear acetate. The decal side of the acetate sheet was then entirely covered with matt white paint (gloss would probably have been better, but matt dries quicker—impatience showing through). When looked at through the acetate I now had a positive image (not mirror), a highly gloss finish (the surface of the acetate), and the acetate protects the decals, win, win, win! All that remained now was to cut and form the panels to fit the model, and the areas not covered by the upholstery were covered in thin aluminium foil to represent the inside surface of an aluminium panel.

Gubby Old Keyboard

It has occurred to me that you may not easily visualise the size of the model, it’s actually quite small, so I thought I’d picture it sitting on my grubby old keyboard.

Getting Tyred?

Quite a while back (couple of years?) I bought some modelling accessories from ‘Speed City’ in the U.S. which included some older type slicks (Firestone Drag 500) which initially I thought would work on this model, but were completely the wrong pattern as I needed what I now understand to be called ‘Piecrust’ slicks. I had absolutely nothing like this and they looked as if they would be a nightmare to produce myself, then, out of the blue, a very good friend of mine returning from holiday in Australia turned up clutching a twin car kit of the vintage Tony Nancy dragsters. Inside the box were—Piecrust slicks! These were terrible renditions of the tyres but they did have the sidewall mouldings, so I carefully pared both sidewalls from one tyre, fitted each to a slightly oversize ring of aluminium and made moulds from which I could cast sets of half tyres. Each pair of half tyres are flatted down until the pair put together were the correct width, (they don’t have to be split in the middle), then glued together, set up in the lathe and the crown filed to size and shape leaving the perfect scuffed finish for a used slick. Exactly the same process was used for the skinny fronts except that I didn’t cut the kit tyres (see pic.).

When flatting down the fronts they obviously become quite thin, and it wasn’t long before I noticed blood all over my ‘wet’n’dry’, I had ground the tips of my fingers away! This wasn’t good, in fact they became very sore and took a long time to heal. Had to find another way to do this. It came by the way of cuttlefish shells, the sort you buy in a pet shop for your Budgies to chew on. Many years ago an old craftsman jeweller had shown me how he could cast silver trinkets in this material simply by impressing an original between two flatted shells. Cut a few tiny air vents and a pour and away you go—it really works! I actually got quite into this for a while and had the wife’s relatives in Italy send me boxes of cuttlefish shells (they live on the Adriatic coast) many of which I still have. The wife’s Italian, by the way—love the cooking! Anyway, I found that I could easily impress the raw skinnys into a bit of shell (leaving the hard shell on the back for strength) and grind to my heart’s content. The same bit of cuttlefish was used for all six half tyres (two spares) and would probably serve for a half dozen more.

A Little Tension

And we come back to the wheels. I knew the pattern of the spokes for the front wheels and had drawn a large scale ‘map’ determining the sequence this would take, so it was just a matter of developing a method. Out came my junk boxes and a trawl through uncovered a threaded brass ferrule of exactly the right diameter and of a comfortable height to accommodate the ‘dish’ of the spokes. The top of this was turned to produce a seat that would locate the rim accurately, and an aluminium spacer made to locate it around the centre of a 14BA brass screw. The thickness of this spacer was calculated to provide the desired amount of ‘dish’ from the centre of the rim. A short length of 1/16” X 3/32” tubing was used for the hub and two brass ‘bearings’ made from old ball-point pen nibs (never throw anything) were machined to a slide fit inside the tubing and drilled to fit over the 14BA screw, this would mean that they would also fit nicely over the 1mm stainless steel stub axles I would make. By the way, the tube used as the ink reservoir in said ball-points fits my airbrush when I use it with a jar (never throw…). A base was made from a bit of old laminate flooring and drilled to accept 9–2BA allen screws on a 3 1/4” p.c.d.— now we could start.

One of the ‘bearings’ was dropped over the 14BA screw to rest on the spacer, the hub tubing was next then a 14BA nut was run down the screw until it allowed about 0.02” free play. A length of 0.006” dia. stainless steel wire was cut from the reel and one end given a couple of wraps around a 2BA screw then superglued. The prepared rim was placed onto the ferrule and the wire stretched across the rim to the 2BA screw almost opposite then given a half wrap around the screw a couple of threads above the baseboard. A little tension had to be held on this while a special tool (a sewing needle with the eye ground back to make a miniature fork) was used to guide the wire into the impressed grooves in the rim and down into the 0.02” gap between the hub tubing and the ‘bearing’. The wire was now guided back across the rim to the next 2BA screw clockwise and the process repeated one screw at a time until the second wire on the first screw was completed, this was given a couple of turns, all the wires checked for tension, then glued. This process can be seen in operation in the photograph with the starting screw bottom right passing to and fro working clockwise as far as the screw extreme left. Once done a tiny dob of superglue was applied to each spoke where it passed over the rim (this was also done with the ground back end of a needle, the tiny fork allowing control over minute amounts of glue). All the spokes were now cut at the outside edge of the rim, the 14BA nut removed, and the half wheel lifted off. The bit of tube for the hub was then removed for use on the other half – the spokes retained their shape and position as the stainless steel doesn’t stretch.

The other half of the wheel was then made in exactly the same way, the two halves, hub, and ‘bearings’ were all passed onto a piece of 1mm stainless steel wire, rotated so that the spokes of each half were at 1/2 pitch to each other, then clamped and glued. A little glue was applied where the ‘bearings’ touch the spokes, then all that remained was to grind down the cut ends of the spokes.

Looking Into the Void

The assembly of the front axle and suspension follows as closely as possibly that of the full size car. The radius arm bolts, batwings, and spring shackles were loosely assembled into the beam. The spring, made from three leaves of 0.008” stainless steel strip, was carefully formed until it’s curvature appeared to match that of the car in static position, then the ends bent up to fit the back of the shackles, cut to length, indented to locate round the top of the swan necks, and glued (spring to shackles). The whole assembly was then attached to the spring perch using a pair of U-bolts, leaving the spring with just enough freedom to allow for a small amount of lateral and radial adjustment. The hairpins were then offered up, cut to length, and clevises fitted to attach them to the batwings. Once the alignment was judged to be about right everything was finally glued together. I then made a pair of friction dampers and coupled them to the chassis and axle via the top clevis of the hairpin. This may not be correct—it is one area to which I have no clear information —but it looks logical. The hub/stub axle/kingpin/drag link/track rod assemblies were made from folded and brazed 0.015” mild steel sheet and stainless steel wire, then fitted to the axle, and once the geometry was set the front end was complete.

By the time this was done the problem of the rear wheels had to be faced. I had made a decision that the only way to simulate the polished finish was to use polished aluminium. The outer rim was turned off the castings down to the spokes and a new one-piece aluminium rim was made with the back relieved to accept the resin hub. I could get an acceptably good paint finish on the spokes so the wheels were assembled ready to fit to the model, however once on the car there was an undesirable empty space when viewed through the wheel. I had no idea what type of brakes would have been fitted, but I sort of hoped they would have been disc brakes so I made up a rudimentary set of discs just adequate to fill the void.

Now that the model was standing on its four wheels there was only the detail work to complete. There were a few sizable items, such as the fuel tank, parachute, safety harness, etc., but mostly very small stuff. It is difficult to realize how small a lot of this stuff is, for instance the track of the front wheels is less than 2-1/4”, and when looking at the photograph of the front end it can be appreciated how awkward it can be for a set of pensionable fingers to manipulate the various pieces prior to glueing (especially if you keep grinding the tips away!). So what I’ve tried to do is incorporate anything which can be clearly seen in photographs, for instance there is what I assume to be a fuel cock just above the front of the fuel pump, operated by a Bowden cable. I made the lever for this, but when I came to fit the cable I decided this was a step too far – it can’t be seen in the vast majority of photographs so it is not on the model.

A Few Regrets

I have really enjoyed building this model. I am certainly developing some new skills and thereby broadening my horizons for the future. It was Gary’s rapid response to my appeal for information which really kicked the project into life and for that I shall be eternally grateful, as it has opened the door into the world of resin casting. Still flushed with enthusiasm I am eager to get started on my next venture, which may yet be the Allard dragster, but on looking back I do have some regrets about not modelling in a larger scale. It would definitely not have been more difficult nor taken any longer to have modelled to 1/8 scale, and would have produced a much more spectacular end result.

We are in early December now and I think the ‘missus’ would prefer me to concentrate on Christmas and the new year. She is a long suffering and patient wife who puts up with me spending long hours in the workshop without complaint so I guess I owe her that—the key has been turned in the workshop door and the spiders can go about their business in peace. I can hardly wait to see what decision the new year brings.

Nicely done! I built a model this way back in ’65, making the frame from scratch pieces of other frames, combining both plastic and metal to make workable steering, same steering. I didn’t make my own wheels, but added hex nuts from watches to look like lug nuts. made giant slicks, using stock rubber thin tires up front. I used a rubber band for blower belt, using copper wire with clear covering for gas line to small moon tank on front axle, perpendicular… The dash had tiny lights behind clear plastic headlight lenses, had a spring-loaded cloth parachute that popped at the end of a run, opening. used colored wire for spark plug lines, used copper wire to build linkage to blower… painted frame white, a ’32 Ford body (firewall to rear only), with 20 coats of candy apple blue and clear. built my roll cage from more plastic mold trims (gates)… complete with seat belt and harness out of leather… fake buckles. I won a prize with it, can’t remember what magazine, 4 page layout and cover… taillights worked with dash lights and under-frame under engine running light operated by camera battery. Shifter of 5-speed trans was made from a gold-plated paper clip, a fake white skull, stuck up 2″ , ha. The throttle pedal operated linkage to blower… ah… I figure I worked 200 hrs on it at least. I trashed it a few months later after a fight with my dad about all my stored parts in my clothes drawer, ugh. Never threw anything in anger since! not worth it. ha. Later, I would become a flute maker in Boston, silver soldering, injection molding silver, gold, platium… etc. Got my skills from playing with models! ah.. including how to use lathes and milling machines… the big ones, ha. Nice work on this model, and I grew up knowing the Steinegger & Eshenbaugh dragster, having seen it at Detroit Dragway, where I got to ride the G.E. Jet bike and others… same left lane, ha. Cheers & thanks…

Did you ever get back to the Allard Chrysler?

What scale is the model?