Reproduction of Milton J. Antonick’s 1955 First National Senior Scholarship, $4,000 Award Winning Guild Model

by Milton J. Antonick, Detroit, Michigan

Since Fisher Body no longer exists and GM apparently destroyed all contest models, I elected to rebuild the 1955 model which was purchased by GM. Part of the model would be re-fabricated utilizing conventional techniques but a portion of the model would utilize contemporary methods. The style, design, and scale would remain unchanged. Photos, plans, and a mental image would provide adequate information.

These days all product design utilizes some form of computer aided design. The program I utilized was Alias which is a 3-D program supplied through Auto-Desk. The program performs well when operating through Windows software and Dell hardware, but other systems can be utilized. This program offers sketch, modeling, and rendering capability. 2-D information can be imported directly. Math data can drive 3-D hardware such as milling machines and rapid prototype machines. ‘Water-tight” and Class A surfacing is possible.

The program will talk to other 3-D programs such as Ideas, Unigraphics, Pro-E. The exchange normally takes place via IGES.

Before the age of computers, one man-year was required to develop an automobile surface in the auto drafting departments. The first cad systems, such as CGS took as long but offered the potential of shared information.

The surface data I developed for the Boston model probably took as much time to develop as the original model. The big time saver is the duplication process from the half model state to full-model state. The seats and interior door trim were much easier to accomplish by computer. The seats had a repeated pattern which develops quicker via computer.

Organic forms can sometimes be a challenge because the system does not provide a sense of touch. The only communication with the form is by way of mouse, key-board and monitor. Although surface development is periodically checked by subjecting the surface to reflective and shading environments, proportional form relationships are difficult to evaluate. The auto industry still utilizes full-scale models during the development process.

Reproduction Guild Model. Made by Milton J. Antonick from Mt. Vernon, Ohio of his 1955 First National Senior Scholarship, $4,000 Award winning Guild model entry (designed and constructed at age 18). Mr. Antonick was a 1953-1955 Guildsman. He had his career in automobile design at Studebaker (Avanti), Chrysler/Plymouth (Valiant and Barracuda); V.P. of Design, William Schmidt Assoc., ALIAS Professor, College for Creative Studies (Detroit), and as a Freelance Designer.

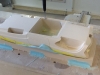

With the Boston reproduction, it wasn’t until after holding the milled model that I realized where and how much the model was “off.” This form data was somehow recorded and retained for over 50 yrs!

Other than the math data development the Boston model build utilized similar methods and materials where possible. I somehow retained the brass bar used for the original wheels! Aluminum is now available in a very hard alloy which does not clog a file. I substituted this material for the fabrication of the” bat wing” rear bumper. The original was a multi piece copper affair. Fabrication was a nightmare and I would never attempt that again. The original gull wing front bumpers were made from 1/8 inch copper bar. I utilized soft aluminum for the Boston model.

I used brass H-O gage rail road track for the original windshield frame. Two pieces were brazed together. H-O rail track now is only available as a chrome nickel alloy. Although it does not require plating it is difficult to form. Both windshield frames were formed over an aluminum template which represented the windshield and also served as a template for the acetate windshield. I did not form acrylic for either model.

The grill on the ’55 model was fabricated by sandwiching thin aluminum sheet. The assembly was screwed together, shaped, taken apart, and offset. Alternate bars were either polished or painted flat black. I used the exact method for the Boston model.

Lathe work provided easy resolution of gauges, shift and steering wheel components for both models. Hardware plumbing supplied necessary copper for rear bumper tubes and interior parts.

Although chrome plating is now available for aluminum I did not plate the Boston model parts.

Correct paint is available because of the auto restoration market. The colors I utilized may have been the most popular GM colors of that time period.

Paint prep has not changed. I used 220 wet and dry sandpaper before primer coat. 400 grit was used before the color coat. The color coat was sanded and polished utilized conventional cleaners and wax. Today very fin grit sandpaper is available. Today clear coating is a common practice. I did not clear coat the Boston model because the original was not clear coated and because sanding and polishing results in a desirable patina.

Metal work received the same sanding, polishing approach. I did not utilize a polishing wheel on either model. Ultra-fine sandpaper reduced polishing time on the Boston model.

The original model probably had more ‘snap’ due to the utilization of lead in red paint and chrome plating. Everything was glued or screwed together with the idea of surviving the trip from Mt. Vernon to Detroit. The gaps and joints were tighter than the Boston model.

That’s not to say the Boston model would not survive a side to side comparison but that the judging back then was a high level.

Wonderful story!

MIlton Antonick’s model is one of my favorite Guild winners.

His original would have been rite at home parked next to any of the 1955 Motorama cars, done by Earl’s “professionals”.

While its a crime that GM destroyed it, it’s awesome that Mr Antonick took on the task of building this fantastic recreation! Thanks for sharing . Marty Martino

Thanks for attending the Boston show-my wife and I were pleased to meet you and the other guildsmen that weekend! I remember seeing your model during the “meet and greet” at the hotel the afternoon before the MFA event took place. Also seeing you completely take it apart and reassemble it in front of us. I was quite impressed with your seminar demonstrating how you were able to recreate your model using Alias software once again using today’s technology.

Milt,

Thanks for sharing the processes you used to recreate your FBCG Award Winning Model Car anew. Your comments about time to develop between your original model and your CAD generated model are worthy of note. Either way, your design was outstanding then/now.

Best regards,

John

John M. Mellberg

1966 FBCG National Award Winner

One of the beautiful 1/24th scale GSL models (not a Guild Model) shown in Salt Lake this year was created using the 3D layer by layer printing process. A cad model must still be prepared, but the printing process creates a detailed, intricate model. This opens up the intriguing possibility of recreating some of the best Guild models that were lost or destroyed years ago. This could be another way to bring back to life some of these beautiful historic models.

Thanks everyone for the great feed-back. Ron, for what it’s worth, I also have a plastic or 3-D printed version of the model. It’s hollow, with a wall thickness of about 4 mm. We have a new 3-D printer at CCS which at the moment has a few bugs but holds great potential for small model building. The College has four machines which are are utilized during the school year for industry sponsored student projects.

Milt Antonick

Enjoy these articles. Do not understand why the models were destroyed.