How A Body is Developed At General Motors

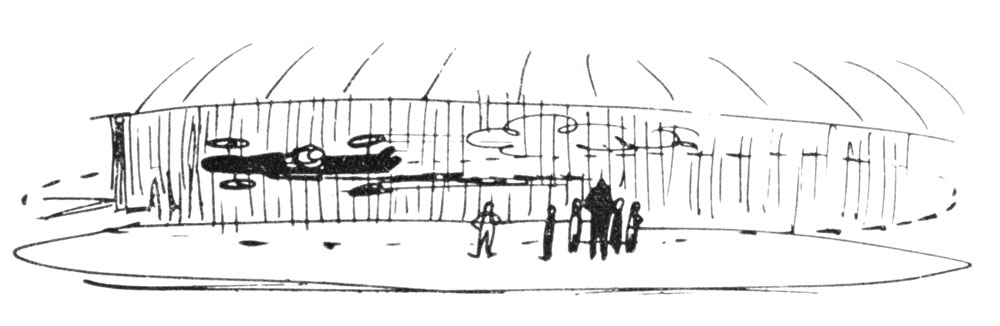

From Stan Mott: Digging through my files, I found this one. It’s the first published satire I did on GM Styling, running in something like 1955 or 1956 in Industrial Design magazine. It took apart the neatly complimentary article in a previous issue. I particularly enjoyed having the prototype racing around the inside of the vertical circular walls of the GM Styling Show Room.

G. T. Christensen wrote:

“Detroit” Postscripts (letters to the editors): “This story makes all other writeups seem inferior. On behalf of all of us in Styling, we want to extend our highest complements.”

G.T. Christensen

Administrative Assistant, Styling

General Motors., Detroit Michigan

Below Christensen’s letter, Industrial Design published Stan Mott’s take on the article:

Policy Meeting: The President of the Corporation, Harlow Curtice, and his to p management committee decide there shall be a new body for the Chevrolet line in 195X. Present at the meeting is the General Manager of Chevrolet, and the Vice President in charge of Styling, Harley Earl.

The President officially notifies Earl of the new assignment.

Presentation of the Problem: Vice President Earl calls a meeting with the Director of Styling and heads of the Chevrolet Studio (Studio C) and the Advanced Body Studio, to discuss the objectives and character of the new line.

Division Engineers (Chevrolet and Fisher Body engineers) are contacted by the studio heads to obtain the latest data n new developments and technical limitations.

Preliminary layout is compiled from all available engineering data, setting specific measurements for ground clearance, seating points, overhead clearance, cowl point, and overhang.

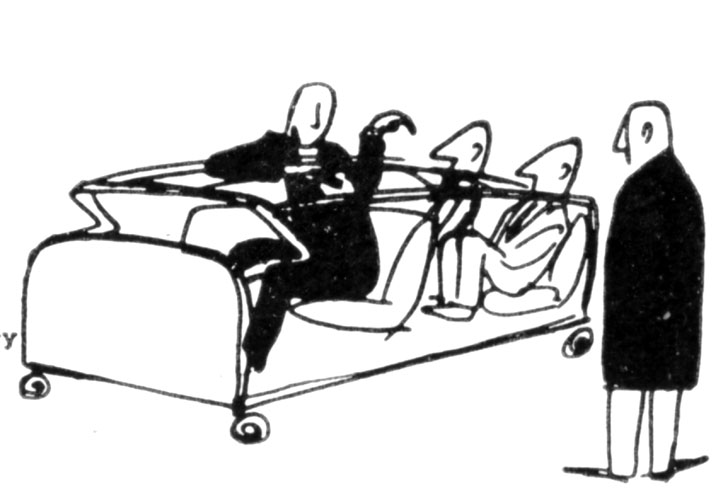

Seating Buck, or rough wooden mock-up, of the body section is constructed from these preliminary measurements. Designers and engineers test the measurements by climbing in and out of the buck.

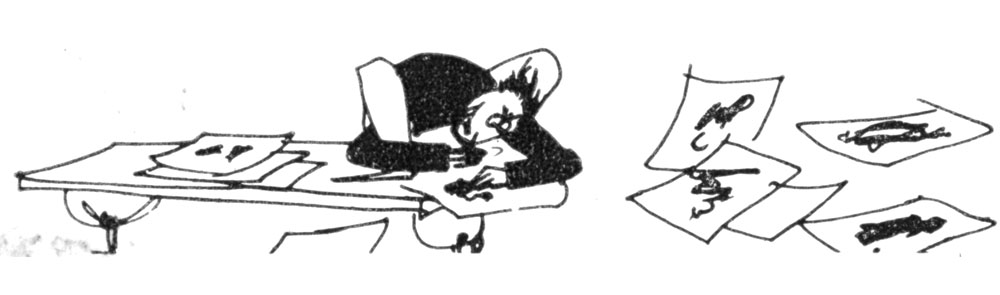

Search for design begins. Each studio, working independently with the preliminary layout, begins to develop sketch ideas that will lead tto a new styling direction.

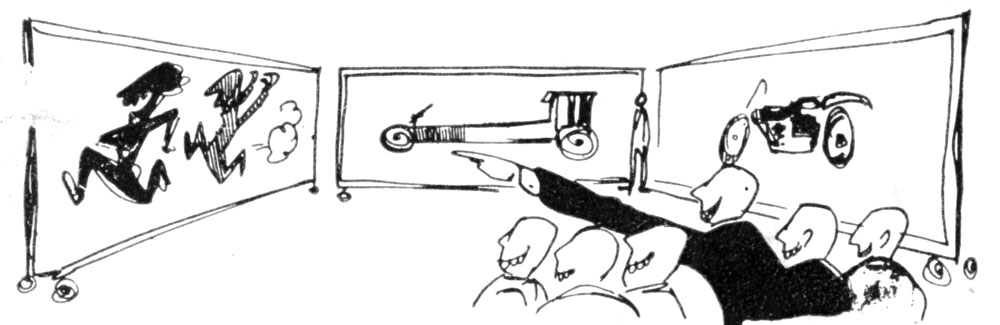

Sketches are reviewed periodically in each studio by the Vice President of Styling, the Director of Styling, and each studio head. A number of treatments —either the entire car, or more typically, a front, back, windshield or roofline—are picked out for further development. Several may be combined.

Full scale proposals are reviewed by the Vice President Earl and his design committee. From these renderings they begin to isolate direction for the new line, again selecting ideas which are worth further development.

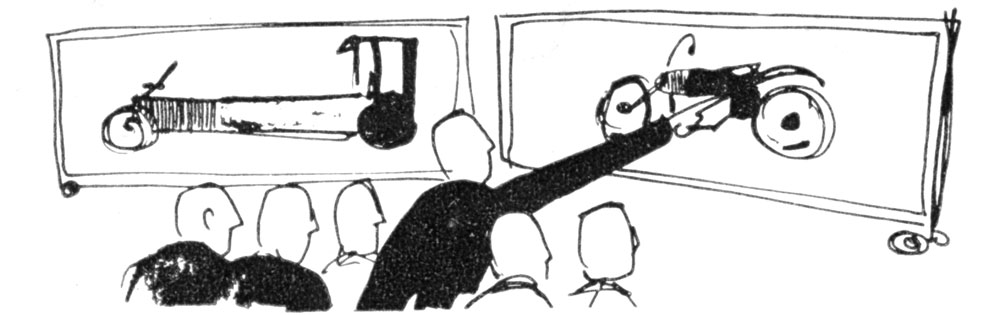

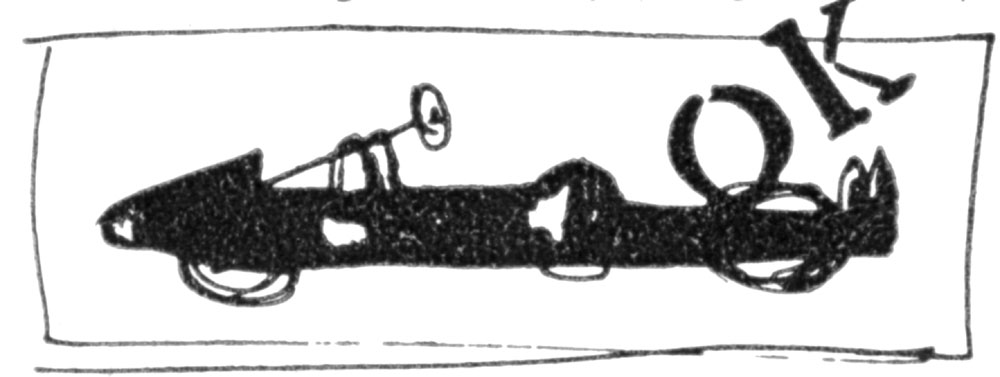

With these selections as starting specifications, the studios again make sketches and another set of full-scale renderings. Generally the Advanced Body Studio concentrates on the general theme, while studio C develops ideas for characteristic detail. The melting-down process ay be repeated 2, 3, or 4 times, as ideas from each presentation are tried in new combinations or in new ways until the design committee finds one solution that successfully incorporates the characteristic features it is seeking. When the all agree on one, they give it the OK.

This is the Kick-off—the basic body concept on which the new Chevrolet line, and possibly other lines, will be based. With the kick-off as a starting point, Studio C designers take over and begin to rework the parts that will assure them of a distinctive product: front end, rear end, final roof line, backlight, and all of the details and trim. After another round or two fo sketches and full-sized renderings, the new Chevrolet proposal is OK’d by the design committee. It is time for 3-dimensional studies…

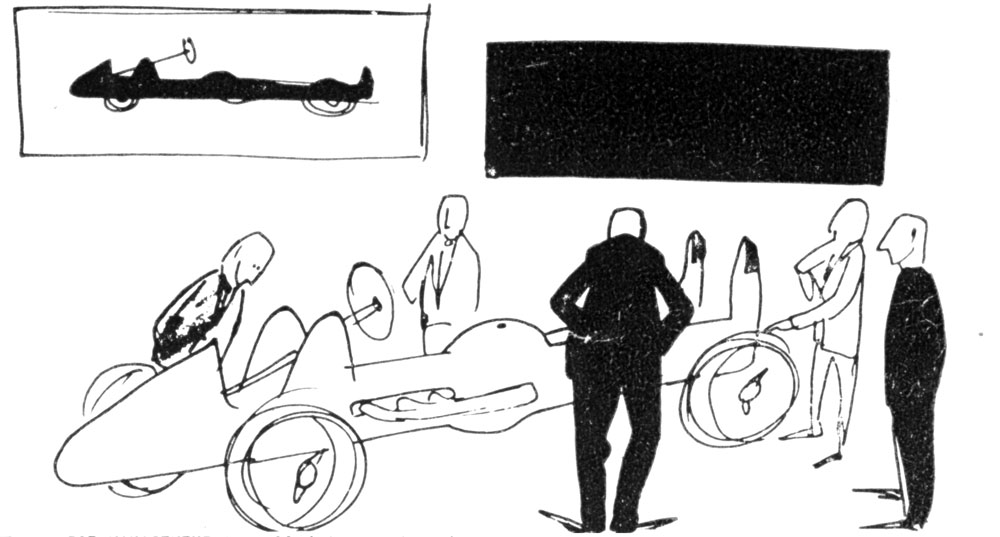

Clay Models: Studio C begins to transform its OK’d rendering into a full-scale clay model. Changes are made during modeling—frequently major ones—and all surfaces and lines are refined. An accurately-measured blackboard drawing or body draft keeps pace with event he slightest changes. From this templates are made, from which body dies will be produced. Top management is called in to view the finished clay model: The President, Manager and Sales Manager of the Division, and Fisher Body engineers are among those who give the OK. Changes may be suggested and made before the approval is final.

Plaster casts are made from the perfect clay model, and a final fiberglass model is made from the casts. This is trimmed and decorated to the last detail to represent the finished car.

The finished model is taken to the test track to be viewed in motion in daylight. Only in natural light can highlights be accurately checked. If no problems show up, the. Chevrolet is ready for production.

I love the sketches, especially the people…. Brilliant.

The process description has lost a lot of impact through the years. I guess that if you never experienced it you probably would find it funny but in the face of the humor of today it is a little mild, simplistic and low key.

If you went through it as many times as I have, addressing the subject, it is amazing how different each experience in creating a car was, no two were ever the same, no two were even close. For me, some were unbelievably easy as the track defined was clear and fruitful. Some of the others that I experienced were very frustrating and difficult to say the least. Usually working long days, Saturdays, sometimes Sundays and even twenty-four hour shifts for several days in a row. And, sometimes very sadly, after all that the project would be cancelled. You were expected to go on and you did with great humor, the one element that was like glue present throughout the building.

The two camps, the studio and the management were not always in sync. Trust was the singular element that would lead to success and if the studio was strong enough to gain control management would be placed in a reactionary position. Then you had it made. They helped a lot, putting together the right team of people, encouraging and mentoring. One thing was certain, they respected hard work and perseverance. They would move things along when the studio lost track of the vision. What was especially satisfying was when management started to delight in the progress that a design was making as we managed the themes, form language and proportion. It was not always easy in the earlier days when the platform developed by engineers was thrown over the wall to the designers to live with. That very important effort was missed in the story.

I can only surmise that many at Styling in the fifties were learning to be designers on the job. It could be years before a designer could actually see enough of his work in clay to start discovering what artistic character in a car that he would actually like and be proud of.

Missed also was the flexibility of the process which led to great success and the creation of the greatest industrial design complex in world history. It raised America up. Everything was provided to foster creativity, absolutely nothing was lacking. The place was inspiring in itself if you had time to look around. Every one of the very specially chosen people throughout the place, the tools created to do the work and the need. Through the years all of that would knit together to become a creative force that demonstrated great success and sometimes failure.

All you had to do was to do it.

If you had the talent, the determination and the will.

Dick Ruzzin

Beautifully expressed and written Dick. You give further clarity to the story from the perspective of one who lived the dream too and realized fulfillment along the way… Thanks!

Kind regards,

John

John M. Mellberg

If you’re referring to the “How A Body Is Developed in General Motors” satire, John, I’m afraid I did all the cartoons presenting G.M. staff as the clowns, buffoons, nitwits and innocents as I saw them. And still do.

Stan is referring to this post, How Cars are REALLY Designed in Detroit. http://www.deansgarage.com/2011/how-cars-are-really-designed-in-detroit/